- Description

Description

The Benefits and Applications of Aluminum CNC Machining Parts Manufacturing

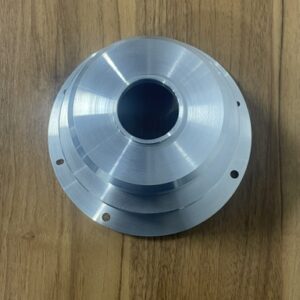

Aluminum CNC machining parts manufacturing offers a multitude of benefits and finds extensive applications across diverse industries. Let’s delve into the detailed description of these benefits and applications:

Precision Engineering

- Aluminum CNC machining enables the production of highly precise parts with tight tolerances and intricate geometries.

- The CNC machines follow programmed instructions meticulously, ensuring consistent and accurate results.

- This level of precision is particularly crucial in industries such as aerospace, automotive, and electronics, where even minor deviations can lead to significant issues.

Durable and Lightweight Components

Aluminum is inherently lightweight, making it an ideal choice for applications where weight reduction is critical, such as aerospace and automotive industries.

Despite its lightweight nature, aluminum CNC machining parts maintain exceptional durability and structural integrity, meeting stringent performance requirements.

Corrosion Resistance

- Aluminum exhibits excellent corrosion resistance, making it suitable for use in harsh environments and outdoor applications.

- Components manufactured through aluminum CNC machining are less prone to rust and degradation, ensuring longevity and reliability in various operating conditions.

Efficiency and Productivity

- Aluminum CNC machining offers high efficiency and productivity, reducing manufacturing time and costs associated with manual labor.

- CNC machines can work continuously, minimizing downtime and maximizing throughput, thereby increasing overall productivity in manufacturing processes.

Properties of Aluminum Alloys Used in CNC Machining

Aluminum 6061

- Aluminum 6061 is one of the most commonly used alloys in CNC machining.

- It boasts excellent mechanical properties, making it suitable for a wide range of applications.

- Aluminum 6061 is known for its ease of weldability, allowing for efficient fabrication processes.

- This alloy is characterized by its medium to high levels of hardness, making it ideal for machining operations.

- Additionally, aluminum 6061 is easy to anodize and bend, further enhancing its versatility.

Aluminum 7075

- Aluminum 7075 is renowned for its high strength-to-weight ratio, making it suitable for applications requiring superior mechanical properties.

- This alloy offers exceptional impact resistance, making it a preferred choice in industries such as aerospace and sporting goods.

- However, aluminum 7075 is not recommended for welding due to its composition, which can lead to issues during the welding process.

- Despite its excellent mechanical properties, aluminum 7075 exhibits high corrosion resistance, ensuring durability in challenging environments.

Aluminum 2024

- Aluminum 2024 is commonly used in aerospace and military applications, where durability and performance are critical.

- This alloy is prized for its good wearability and high corrosion resistance, particularly in harsh operating conditions.

- However, aluminum 2024 is considered a challenging material to weld due to its composition, which may require specialized techniques.

- Despite its limitations in weldability, aluminum 2024 offers exceptional mechanical properties, making it suitable for demanding applications.

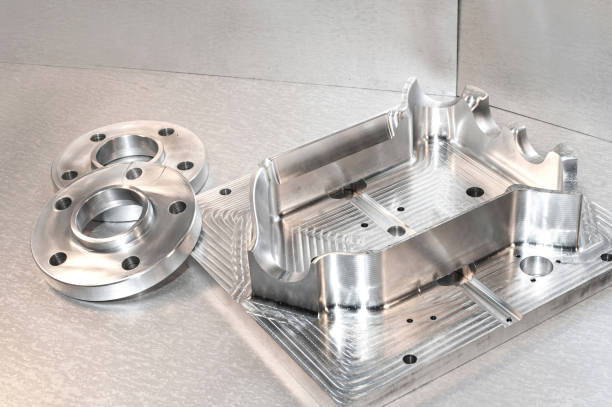

Applications of Aluminum CNC Machining Parts

Aerospace Industry

Examples of Critical Components Produced with Aluminum CNC Machining:

- Brackets: Aluminum CNC machining is utilized to manufacture brackets used for mounting various components within aircraft structures. These brackets are essential for ensuring structural integrity and proper assembly.

- Housings: Aluminum CNC machining is employed to produce lightweight yet durable housings for critical aerospace components such as avionics systems and navigation instruments.

- Panels: Aluminum panels produced through CNC machining are used in aircraft interiors and exteriors, providing structural support and aerodynamic efficiency.

Automotive Industry

Utilization of Aluminum CNC Machining for Lightweight Engine Components:

- Engine Blocks: Aluminum CNC machining is employed to manufacture engine blocks, providing the necessary strength and durability while significantly reducing weight compared to traditional materials such as cast iron.

- Cylinder Heads: Aluminum cylinder heads produced through CNC machining offer superior thermal conductivity and lightweight properties, enhancing engine performance and efficiency.

- Transmission Housings: Aluminum transmission housings manufactured via CNC machining contribute to weight reduction in automotive transmissions, improving fuel efficiency and overall vehicle performance.

Electronics Industry

- Importance of Precision-Manufactured Aluminum Parts in Electronic Devices:

- Heat Sinks: Precision-manufactured aluminum heat sinks are essential components in electronic devices, dissipating heat generated by electronic components to ensure optimal operating temperatures and prevent overheating.

- Enclosures: Aluminum enclosures produced through CNC machining provide housing and protection for electronic components, ensuring durability, electromagnetic shielding, and aesthetic appeal.

- Connectors: Precision-manufactured aluminum connectors play a crucial role in establishing electrical connections within electronic devices, offering reliability, durability, and compatibility with various interfaces.

Challenges and Considerations in Aluminum CNC Machining

Weldability Issues with Certain Aluminum Alloys

- Some aluminum alloys, such as 7075 and 2024, pose challenges in terms of weldability due to their composition and metallurgical properties.

- Welding these alloys may result in issues such as cracking, porosity, and reduced mechanical properties, necessitating careful consideration and specialized welding techniques.

- Weldability issues with certain aluminum alloys can impact the design and manufacturing process, requiring alternative joining methods or material selection to overcome these challenges.

Specialized Machining Techniques for Different Alloys

- Aluminum alloys exhibit varying hardness, machinability, and thermal properties, necessitating specialized machining techniques to achieve optimal results.

- For example, alloys like 6061, known for their ease of machinability, may require standard machining practices, while harder alloys like 7075 may necessitate slower cutting speeds and higher feed rates.

- Specialized tooling, cutting parameters, and machining strategies are often employed to maximize efficiency and precision in aluminum CNC machining operations.

The Significance of Optimizing Design and Material Selection

- Material selection plays a crucial role in aluminum CNC machining, as different alloys offer distinct properties and performance characteristics.

- Choosing the right alloy for the intended application involves considering factors such as mechanical properties, corrosion resistance, and weldability, among others.

- Design optimization is essential to ensure manufacturability and performance of aluminum CNC machined parts, minimizing material waste, production time, and costs.

- Collaboration between design engineers and CNC machining experts is vital to optimize part geometry, tolerances, and surface finishes, maximizing the efficiency and effectiveness of the manufacturing process.

TDB Hanoi Co., Ltd a pioneering name in the realm of multi-axis CNC machining and Aluminum CNC Machining parts in Vietnam since 2015. Committed to upholding stringent quality standards, we have established ourselves as a reliable partner for precision manufacturing. Our state-of-the-art facility boasts over 50 CNC machines and an extensive selection of more than 100 metal materials, ensuring versatility and efficiency in meeting diverse customer needs. Count on us to deliver your parts with precision and punctuality, every time.

Conclusion

The utilization of Aluminum CNC Machining parts offers a multitude of benefits across various industries. From aerospace and automotive to electronics, the lightweight, durable, and precision-engineered components manufactured through CNC machining play a pivotal role in enhancing performance, reliability, and efficiency.

With careful consideration of alloy selection, specialized machining techniques, and design optimization, manufacturers can leverage the full potential of aluminum CNC machining to meet the demands of modern manufacturing. As technology continues to advance, Aluminum CNC Machining parts will undoubtedly remain at the forefront of innovation, driving progress and shaping the future of manufacturing.