- Description

Description

Enhancing Durability and Aesthetics with Aluminum Anodizing Machined Parts

Introduction to Aluminum Anodizing

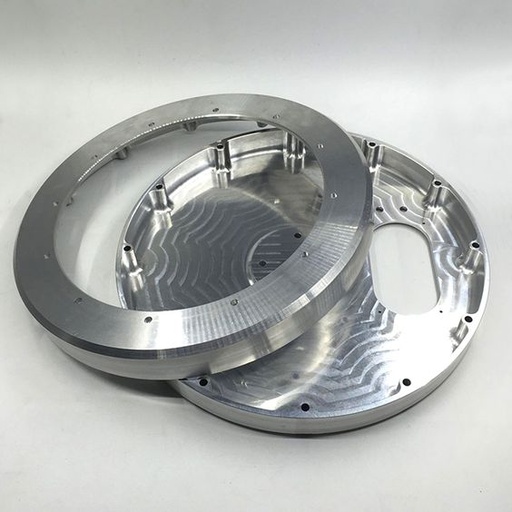

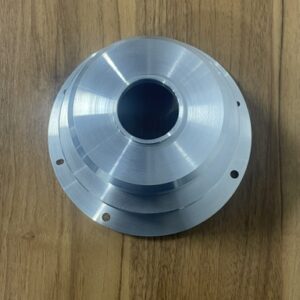

Aluminum anodizing is a process that enhances the surface properties of aluminum machined parts. By creating a protective oxide layer, this technique not only improves the durability of the components but also adds to their aesthetic appeal. Anodizing is widely used in various industries, from aerospace to consumer electronics.

Benefits of Anodized Aluminum Parts

Anodized aluminum machined parts offer several advantages over non-anodized parts. Firstly, they exhibit increased resistance to corrosion and wear, ensuring a longer lifespan. Secondly, anodizing allows for the introduction of vibrant colors to the parts, providing a more attractive finish. Additionally, the process enhances the surface hardness, making the parts more resistant to scratches and other forms of mechanical damage.

Applications of Anodized Aluminum Machined Parts

Aluminum anodizing machined parts find applications in a wide range of fields. In the automotive industry, anodized parts are used for both functional and decorative purposes. In consumer electronics, anodized aluminum provides a sleek and durable finish for devices like smartphones and laptops. Aerospace and marine industries also benefit from the increased corrosion resistance that anodizing offers.

Conclusion

In conclusion, aluminum anodizing is a valuable process for enhancing the performance and appearance of machined parts. Whether you are looking for increased durability, aesthetic appeal, or both, anodized aluminum machined parts provide a reliable solution. As industries continue to demand high-performance materials, the importance of anodizing will only grow.