Swiss Machining

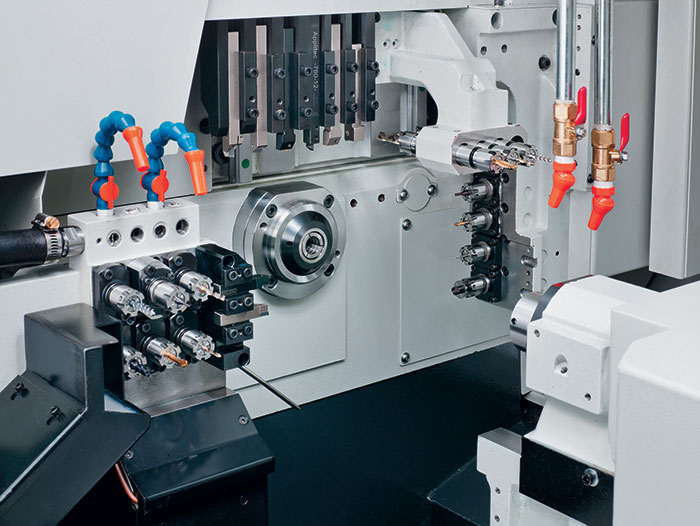

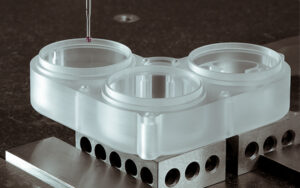

Swiss machining, also known as Swiss turning, is a high-precision CNC process carried out on specialized turning machines designed to produce small and intricate parts. These Swiss lathes operate with incredibly tight tolerances and shorter cycle times compared to conventional lathes, making them ideal for manufacturing complex parts in larger volumes.

TDB excels in the precision manufacturing of intricate machined components with the latest, cutting-edge Swiss lathes. Our state-of-the-art CNC workcenters provide highly accurate, close-tolerance turning operations, ensuring unmatched efficiency and repeatability.

Multi-Spindle Swiss Turning Services with 7-Axis CNC Machining

At TDB, our full-service CNC machine shop excels in delivering highly accurate and efficient Swiss turning solutions. By utilizing multi-spindle Swiss lathes with multi-axis machining capabilities, we significantly reduce cycle times and overall production costs. For intricate components and assemblies that demand complex designs and tight tolerance geometries, our 7-axis CNC Swiss turning services provide the precision and quality your products deserve.

Swiss Screw Machining Capabilities

TDB’s Swiss turning department can handle material diameters up to 32mm, accommodating both shaped and extruded workpieces within this range. Our Swiss lathes efficiently process both solid stock and tubing, ensuring versatility and precision in every project.

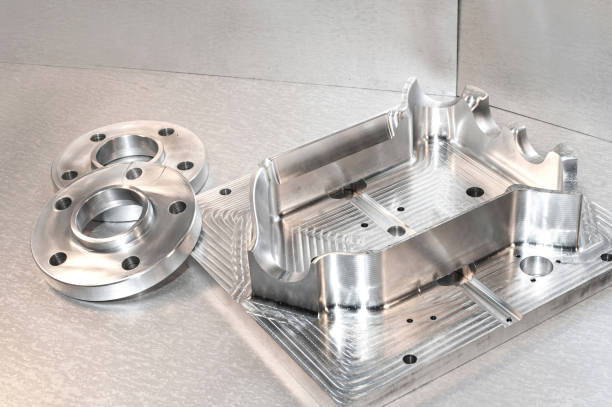

Custom Swiss Turning Solutions for Diverse Material Applications

A wide range of metals and engineering plastics are available for the manufacture of swiss turning parts. We can quickly run mass production using various high-quality materials tailored to your application. Here are some common materials used for swiss machining parts:

Aluminum is a versatile material with excellent machinability, weldability, and plating properties. Its good corrosion resistance, high strength-to-weight ratio, and good temperature resistance make it ideal for CNC machining. After machining, aluminum has a low risk of deformation or defects and is easy to polish and color. Because of these properties, aluminum is widely used across various industries, including automotive, defense, aerospace, transportation, construction, packaging, electronics, consumer goods, and more.

Copper is a highly machinable metal with diverse functions due to its mechanical properties. It boasts good strength, hardness, excellent thermal conductivity, and corrosion resistance.

Brass is a metal alloy composed of copper and zinc, known for its excellent electrical conductivity and good processability. With low-friction properties and a gold-like appearance, brass is commonly used in construction and the manufacture of gears, locks, pipe fittings, musical instruments, and more.

Stainless steel typically contains at least 10% chromium by weight and is known for its desirable properties in many industrial applications. These properties make stainless steel a popular choice across various industries, including construction, automotive, aerospace, and more. Its versatility and effectiveness make it a preferred material for numerous applications within these sectors.

Titanium possesses numerous material properties that make it ideal for demanding applications. It offers excellent corrosion resistance, chemical resistance, and extreme temperature resistance, along with an outstanding strength-to-weight ratio. These properties, combined with its high tensile strength, have made titanium a popular choice in the aerospace, medical, and defense industries.

Plastic is a popular choice for CNC machining because of its wide variety, relatively low cost, and significantly faster machining times. We offer all common plastics for CNC machining services:

|

|

|

|

|

|

|

|

|

|

|

|

CNC Machining Surface Finishing

Swiss machining leaves visible machining marks as it shapes the material. These marks can be removed using various surface finishes, enhancing both the functionality and aesthetics of the part. TDB ‘s CNC Machining Services in Vietnam offers a wide range of standard surface finishes and can help you select a unique finish for your custom parts.

Our standard machined finish provides a surface roughness of 3.2 μm (126 μin), effectively removing sharp edges and cleanly deburring the part.

Applicable Materials: All materials

Color: N/A

Sandblasted parts feature a smooth surface with a matte finish, primarily used for visual applications and can be combined with other surface treatments.

Applicable Materials: ABS, aluminum, brass, stainless steel, steel

Color: N/A

Texture: Matte

Description: Anodizing enhances corrosion resistance, wear resistance, and hardness while protecting metal surfaces. It is widely used in mechanical parts, aircraft, auto parts, precision instruments, and more.

Applicable Material: Aluminum

Color: Clear, Black, Grey, Red, Blue, Gold, etc.

Texture: Smooth, matte effect

Description: Powder coating is a dry finishing process that uses an electric charge to fuse a dry powder to the metal surface. The coated part is then baked in a curing oven to achieve a smooth and durable finish. This method is typically used to create a hard finish that is tougher than conventional paint.

Applicable Material: Steel, Stainless Steel

Color: Clear, Black, Grey, Red, Blue, Gold, etc.

Texture: Smooth, Gloss

Description: Electroplating can serve functional, decorative, or corrosion-resistant purposes. It is widely used in various industries, including the automotive industry, where chrome plating of steel auto parts is common.

Applicable Materials: Aluminum, Steel, Stainless Steel

Color: N/A

Texture: Smooth, shiny surface

Description: Polishing is a process that reduces the surface roughness of a workpiece through physical friction, chemical, or electrochemical effects, resulting in a bright and smooth surface. While polishing does not improve the dimensional or geometric accuracy of parts, it aims to achieve a smooth surface or mirror gloss, and can also be used for matting. This technique enhances the appearance of metal parts, including vehicle components, armrests, cookware, kitchen appliances, and architectural metals.

Applicable Materials: Aluminum, brass, stainless steel, steel, PMMA, PC

Color: N/A

Texture: Smooth