Swiss CNC Machining Service

With 10 years of Swiss CNC machining experience. TDB can deliver your custom swiss parts to build your brand and grow your profits.

- Over 40 Certified Materials

- ±0.005mm Tight Tolerance

- Custom Finishes

- Lead times from 7 days

- Customer data security

Expert Swiss CNC Machining Services From Vietnam

Looking for a dependable, fast-turnaround supplier for CNC Swiss parts?

TDB provides high-precision CNC Swiss machining services to industries such as aerospace, consumer products, automotive, medical, electronics, sports, and other industrial sectors.

Whether you need prototyping or full-scale production, our extensive range of Swiss CNC machines, CNC lathes, and turning centers ensures the delivery of high-quality, precision parts that meet even your most demanding specifications.

What is swiss machining

Swiss Machining is a precision manufacturing process that utilizes computer-controlled Swiss lathes to produce small, intricate parts. Originating in Switzerland, this technique is named after its place of development. Unlike traditional CNC lathes, which typically use a single cutting tool, Swiss CNC lathes feature a multi-axis turret capable of operating multiple cutting tools simultaneously.

This advanced setup makes Swiss CNC machines ideal for creating complex components with tight tolerances. Additionally, their ability to operate at high speeds makes them perfectly suited for high-volume production. As a result, Swiss CNC machines have become an indispensable asset in modern manufacturing operations.

What is the benefit of Swiss Machining

Swiss Machining offers numerous advantages, including exceptional precision, efficiency, and versatility. These qualities make it the perfect choice for producing high-quality, reliable parts across a variety of applications.

Extremely Tight Tolerances

With Swiss CNC machining, you benefit from remarkable precision, ensuring that parts fit and function exactly as intended. This exceptional accuracy minimizes the risk of assembly issues or product failures, helping to avoid costly redesigns or recalls.

High-quality surface finishes

Swiss CNC machines deliver exceptional surface finishes, making them ideal for industries that demand high-quality aesthetics or low-friction components. These superior finishes not only enhance product performance but also elevate their appearance, ensuring greater competitiveness in the market.

More Complex Parts

Swiss CNC machining empowers customers to produce intricate designs and complex geometries, enabling innovative product possibilities. By overcoming traditional manufacturing constraints, it supports the development of advanced, competitive products that stand out in the market.

Fast production times

Swiss CNC machining offers shorter lead times due to its efficient design and minimized setup times. This allows you to accelerate product launches, quickly adapt to market demands, and respond promptly to changing needs.

Consistent quality

Swiss CNC machining is renowned for its exceptional consistency and repeatability, ensuring the production of high-quality parts with minimal variation. This reliability is especially critical for industries with strict quality control standards, such as aerospace, medical, and automotive sectors.

Integrated processes

Swiss CNC machines are capable of performing multiple operations, including drilling, tapping, and milling, all within a single setup. This integrated functionality eliminates the need for additional manufacturing steps, leading to reduced costs and shorter lead times for customers.

Materials We Work With Swiss CNC Machining

No matter whether plastic or metal, at TDB, You Can Choose Freely For Your Unique Request.

Swiss Machining Metal

TDB offers a wide variety of materials for precision swiss machining, metal including but not limited to:

|

|

|

|

|

|

|

|

|

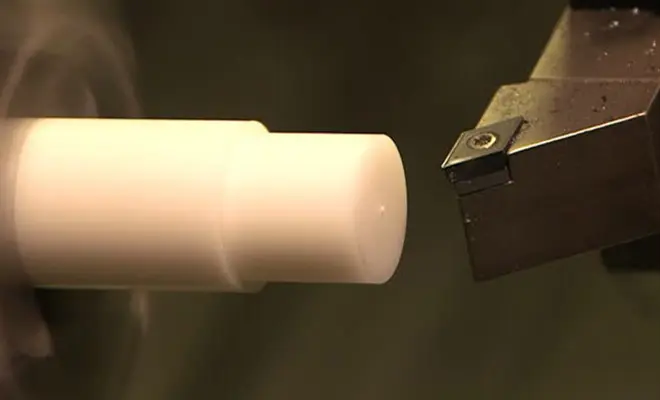

Swiss Machining Plastic

TDB offers a wide variety of materials for custom swiss machining, plastic including but not limited to:

|

|

|

|

|

|

|

|

|

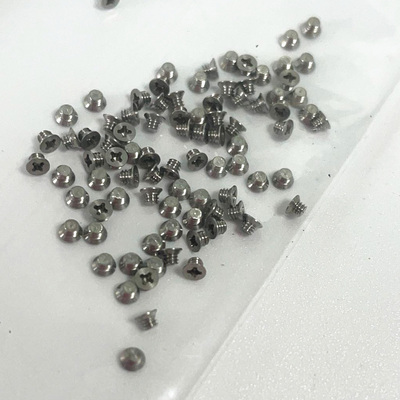

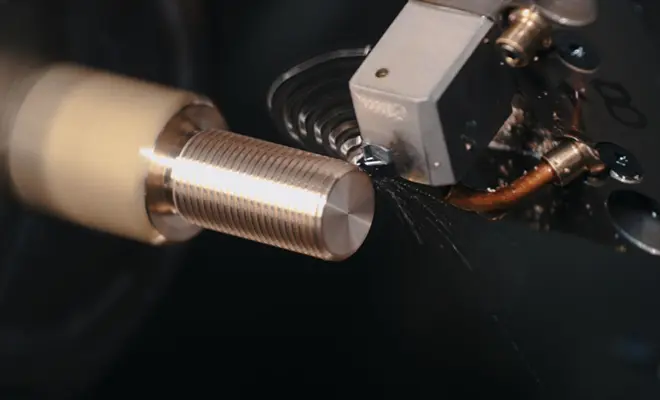

Gallery of Our CNC Swiss Machined parts

We specialize in machining rapid prototypes and handling both low- and high-volume production orders for customers across a wide range of industries, including medical devices, aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, marine, robotics, and more.

Why Choose Us For Swiss Machining Services

Reduce Cost

TDB delivers efficient Swiss CNC machining, combining precision, quality, and affordability. Using state-of-the-art equipment and lean manufacturing techniques, we help you save 40%-60% on costs without compromising reliability.

Tight Tolerances

TDB excels in Swiss CNC machining, offering unparalleled precision through advanced technology, expert craftsmanship, and rigorous quality control. Trust us to deliver accurate components with a steadfast commitment to excellence.

Fast Turnaround Time

We prioritize your deadlines by offering fast turnaround times for Swiss machining services, ensuring short lead times and prompt revisions when needed.

24/7 Engineering Support

Our engineers are available 24/7 to provide expert guidance and technical support for your Swiss machining projects. We collaborate closely with you at every stage to ensure your project is completed on time, within budget, and to your exact specifications.