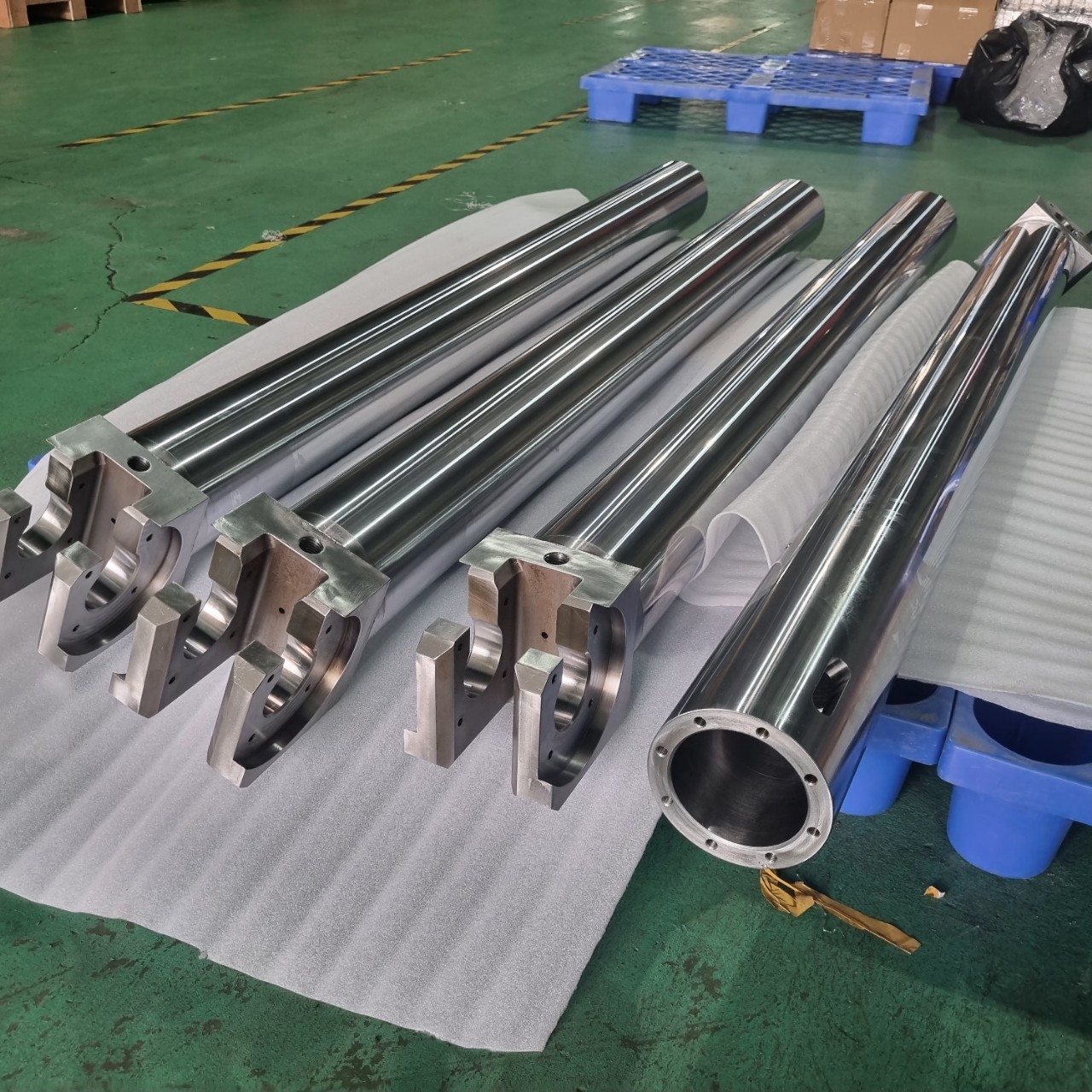

CNC Turning Parts

CNC turned components are vital across numerous industries, ensuring the consistent production of intricate and precisely shaped parts. As industries continue to push the boundaries of innovation, CNC turned components play an essential role in delivering the reliability and performance required for advanced applications.

Leveraging cutting-edge technology and a global network of manufacturing partners, TDB has revolutionized the procurement process, ensuring that clients receive CNC turned components of the highest quality and precision. Their unwavering commitment to excellence, transparency, and efficiency has positioned TDB as a crucial partner in the production and delivery of CNC turned components, elevating standards across industries.

Find out more about our products

We pride ourselves on our exceptional customer service and are available to answer any question you might have about our products.

Frequent Question

Next-Projects Machine Manufacturers

TDB has grown to be one of the leading machining manufacturers in Hanoi, Vietnam, specializing in Machining Engineering Services, Machine Unit Assemblies, and Surface Treatment Solutions. We’ve evolved and expanded our capabilities to offer value-added services, including Box Build and Custom Panel Assembly. With over 1000 square metter of dedicated manufacturing capacity combined with 10 years of industry experience, we have the resources to help our customers achieve success.

Payment Methods: T/T, L/C, Escrow, MoneyGram, etc.

Payment Terms:

- Deposit: 30% to 50% deposit required, with the balance due upon delivery.

- Net 30 Days: Payment due within 30 days of invoice date.

Payment terms can be tailored to meet the needs of each specific customer.

We conduct a series of production processes for your parts:

1. Implement an in-depth study of your requirements

2. Customize production solutions

3. Schedule the production

4. Start the production

5. Monitor the production process

6. Conduct random quality inspections on the product

7. Customize packaging solutions

8. Conduct pre-shipment quality inspection and coordination of shipment logistics

9. Conduct After-Sales Service

Yes, of course. Since TDB provides OEM services, the cost for mold opening may vary depending on the product’s specifications and weight. Please communicate with our business manager to confirm the details.