Manifolds with Stainless Steel 304/316 for Pump Systems

Reviews Summary by AI:

- Description

Description

Introduction to Stainless Steel Manifolds

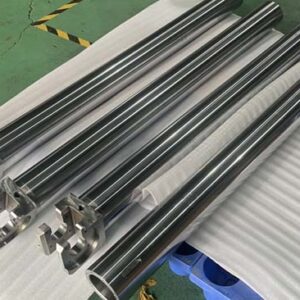

Manifolds are critical components in various pump systems, playing a vital role in distributing fluids efficiently. When it comes to material, stainless steel 304 and 316 are often the top choices due to their superior properties. This article explores the advantages and applications of manifolds constructed with these high-grade stainless steels.

Advantages of Stainless Steel 304/316

Stainless steel 304 and 316 are renowned for their robustness and corrosion resistance. Stainless steel 304 is commonly used in situations where durability and cost-efficiency are paramount. On the other hand, stainless steel 316 contains molybdenum, which gives it an edge in highly corrosive environments, making it ideal for marine applications and industries dealing with aggressive chemicals.

Applications in Pump Systems

Manifolds made from stainless steel 304 and 316 find extensive applications in various pump systems. These include water treatment facilities, chemical processing plants, and oil and gas industries. Their ability to withstand high pressure and corrosive elements ensures the longevity and reliability of the pump systems, reducing maintenance costs and downtime.

Conclusion

Choosing the right material for manifolds is crucial for the efficiency and longevity of pump systems. Stainless steel 304 and 316 offer remarkable advantages in terms of durability, corrosion resistance, and suitability for diverse applications. Investing in these high-quality stainless steel manifolds ensures optimal performance and reliability in any pump system.