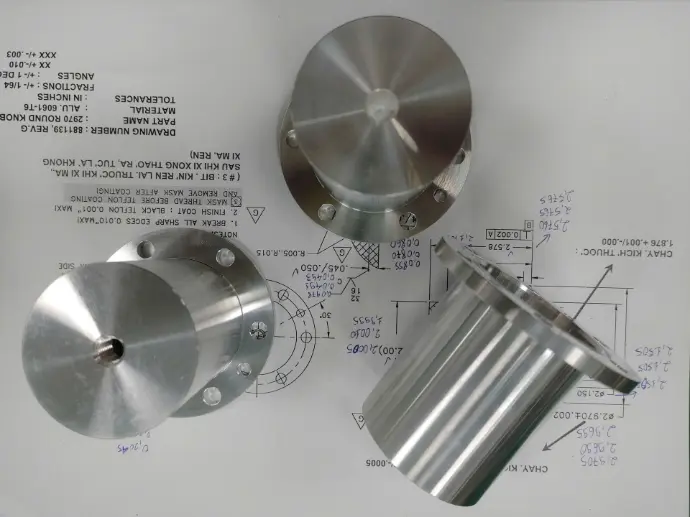

Aluminum

Aluminum is widely utilized across industries due to its excellent strength-to-weight ratio, affordability, and recyclability, making it an ideal material for various applications.

Common Alloys: 6061-T6, 7075-T6, 2024, 5052, 6060, 5083, 2017, 6082

Finishing Options: Alodine, Anodizing (Types II, III, III + PTFE), Electroless Nickel Plating (ENP), Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing

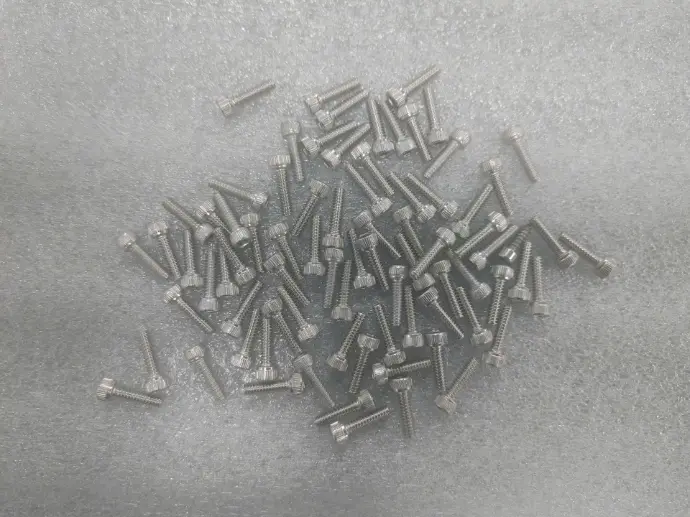

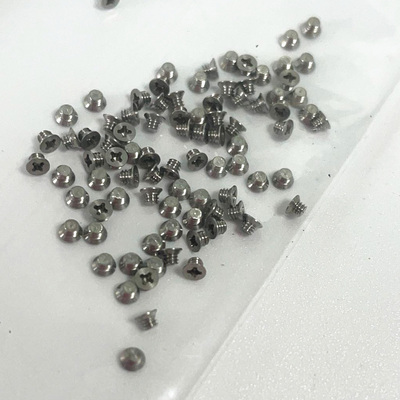

Stainless Steel

Renowned for its excellent corrosion resistance and ductility, stainless steel is ideal for applications requiring long-term exposure to the elements and easy shaping into various forms.

Common Alloys: SS303, Stainless Steel 304/304L, Stainless Steel 316/316L, Stainless Steel 17-4, Stainless Steel 416, etc.

Finishing Options: As Machined, Bead Blasted, Polishing, Decorative Chrome Plating, Powder Coating, Nickel Plating, Gold Plating, Silver Plating

Brass

Brass, an alloy of copper and zinc with a zinc content typically exceeding 20%, is one of the most commonly used materials in CNC machining due to its machinability and versatility.

Common Alloy Grades: C360, C260

Finishing Options: Nickel Plating, Bead Blasting, Gold Plating, Silver Plating

Copper

Copper is a soft, malleable metal known for its excellent thermal and electrical conductivity, making it a vital material in a wide range of industries, including electronics, plumbing, and construction.

Common Grades: C10100, C11000, C12200, C14500, C17200

Finishing Options: Plating, Polishing

Titanium

Titanium is a lightweight yet strong material with a low density and exceptional strength-to-weight ratio, making it ideal for industries such as aerospace, automotive, and biomedical. It is highly resistant to corrosion and can endure exposure to various chemicals and harsh environments.

Common Alloys: Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo, Ti-3Al-2.5V

Finishing Options: Polishing, Anodizing, Sandblasting, Chemical Etching, Laser Engraving, and more