Precision CNC Machining in Vietnam

In the heart of Southeast Asia, Vietnam is rapidly becoming a powerhouse in precision CNC machining. With a perfect blend of skilled labor, advanced technology, and competitive pricing, this country is carving out a niche in the global manufacturing landscape. If you’re an engineer, manufacturer, or simply someone on the hunt for a precision machining shop for custom parts or projects, you might find Vietnam’s offerings both intriguing and beneficial. But what makes Vietnam such a compelling choice for your machining needs?

Could Vietnam’s burgeoning machining industry be the key to unlocking unparalleled precision and cost-effectiveness for your projects?

Key Takeaways

- Vietnam’s machining industry is on a fast track to growth, thanks to significant investments and government support

- Leading Vietnamese companies are making waves in the international market with top-notch quality and innovative approaches

- Green manufacturing and smart technologies are emerging trends, setting new standards in the industry

- Competitive pricing and high standards make Vietnam an attractive choice for precision machining needs

- Vietnamese machine shops offer extensive services, from CNC turning and milling to prototype development

Exploring the Landscape of Precision Machining in Vietnam

Vietnam’s precision machining landscape is a dynamic field, bustling with innovation and growth. The country’s journey into this industry is marked by rapid advancements backed by strategic investments and a commitment to quality. For anyone looking to find the perfect precision machining shop, understanding this landscape is crucial.

The Growth of the Machining Industry in Vietnam

Over the past few years, the machining industry in Vietnam has experienced a remarkable growth spurt. This surge is largely due to substantial investments from global companies recognizing Vietnam’s potential as a manufacturing hub. The influx of foreign capital has spearheaded industrial development, fueling a sector that thrives on precision and innovation.

The Vietnamese government has played a significant role in this expansion, offering support that has elevated the country’s machining capabilities. With policies fostering industrial growth, Vietnam has emerged as a competitive player in the precision parts market. As demand for precision parts climbs, technological advancements are continually being integrated, keeping Vietnam at the cutting edge of machining services.

Key Players in the Vietnamese Precision Machining Market

Vietnam is home to several key players in the precision machining market, each establishing a formidable reputation for quality and innovation. These market leaders, ranging from large firms to nimble startups, have crafted a niche for themselves by consistently delivering excellence.

International partnerships have been pivotal in enhancing the capabilities of local shops. By collaborating with global giants, Vietnamese companies have access to state-of-the-art technology and techniques. This synergy has not only bolstered their precision machining shop offerings but has also positioned them as market leaders. Continuous investments in the latest CNC machining technologies underscore their commitment to staying ahead in the game.

Emerging Trends in Machining Services

Vietnamese companies are at the forefront of adopting emerging trends in machining services. Green manufacturing practices are gaining traction, driven by a growing awareness of environmental sustainability. More and more, businesses are integrating smart technologies, enhancing their CNC machining processes and delivering precision like never before.

The demand for customized solutions is surging, with industries seeking tailored approaches to meet their specific needs. This rise in bespoke machining services is complemented by the increasing use of collaborative robots, or cobots, which streamline operations and boost efficiency. As these trends gain momentum, Vietnamese machining services continue to evolve, setting benchmarks in precision and innovation.

Why Choose a Vietnamese Machine Shop for Your Projects?

Deciding to go with a Vietnamese machine shop could be one of the smartest choices you make for your project. Known for their competitive pricing and high-quality standards, these shops offer a range of advantages that can be hard to match elsewhere.

Competitive Advantages of Vietnamese Machine Shops

Vietnamese machine shops are synonymous with competitive advantages. They offer some of the most cost-effective solutions without sacrificing quality. The skilled labor force, coupled with modern facilities, ensures that production capabilities are top-notch. These shops have perfected the art of balancing cost with exceptional quality, making them a go-to choice for many.

Strategically located in Asia, Vietnam provides logistical benefits for global shipping. This strategic position simplifies the supply chain, reducing lead times and costs. Add to this the flexibility and adaptability of Vietnamese shops, which are adept at handling custom projects, and you have a recipe for success.

High-Quality Standards and Precision

In every step of the manufacturing process, Vietnamese shops prioritize high-quality standards. Adhering to international benchmarks, they ensure that each product meets the precision requirements necessary in today’s competitive markets. Cutting-edge technology is employed to maintain tight tolerances, ensuring that quality parts are produced consistently.

Continuous quality improvement is not just a buzzword—it’s a core focus for many Vietnamese firms. By investing in the latest equipment and training, these shops ensure their machining services are among the best in the business. This dedication to quality and precision makes them a reliable partner for your projects.

Cost-Effectiveness of Machining Services in Vietnam

One of the primary draws of Vietnamese machining services is their cost-effectiveness. Competitive labor costs play a significant role in keeping prices attractive. Advanced technology further reduces waste and enhances production efficiency, allowing shops to offer excellent value for high-precision projects.

These cost savings are not just on paper. They translate into tangible benefits that can be reinvested into other areas of your business. Choosing Vietnam for your machining needs means you get quality and precision at a fraction of the price you’d expect elsewhere.

Top Precision Machining Services Offered in Vietnam

When it comes to precision machining, Vietnam offers a comprehensive suite of services that cater to diverse industry needs. From CNC turning and milling to multi-axis machining, the capabilities are vast and impressive.

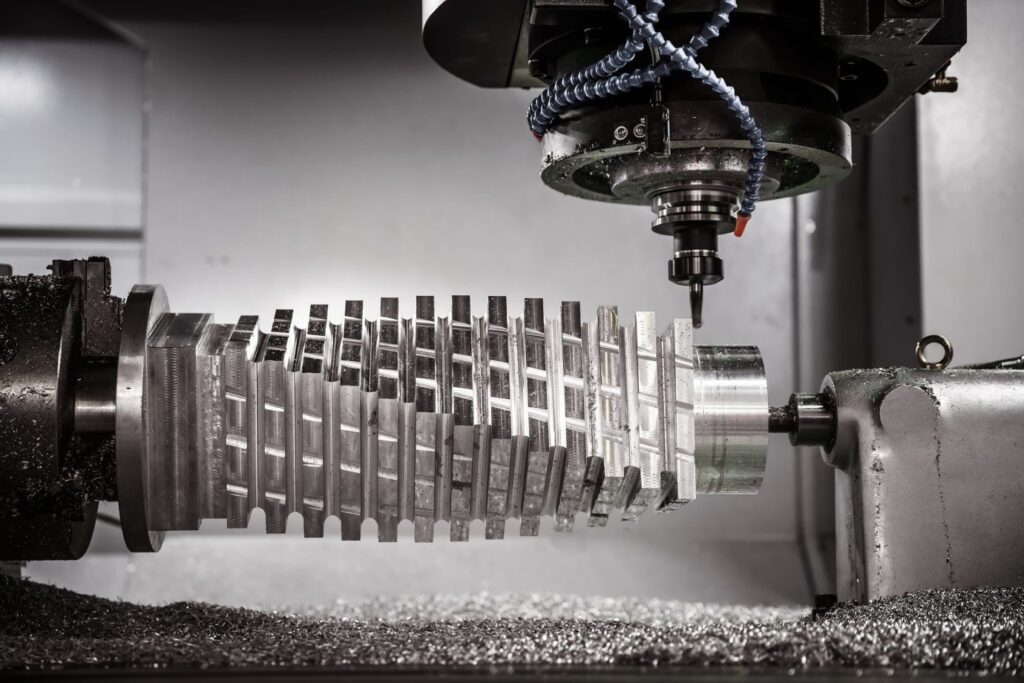

CNC Turning and Milling Services

Vietnamese companies excel in CNC turning and milling services, delivering high precision for both cylindrical parts and complex shapes. With advanced software, these machining processes are efficient and accurate, ensuring that even the most intricate designs are executed flawlessly.

Whether you’re dealing with small batches or large-scale production, Vietnamese precision machining shops are equipped to handle it all. Their ability to maintain superior accuracy across varied project sizes makes them a versatile choice for any industry.

Multi-Axis Machining Capabilities

The multi-axis machining capabilities of Vietnamese shops allow for intricate designs and complex geometries. By reducing the need for additional setups and tooling, these capabilities streamline the production process, ensuring quicker turnaround times for projects.

High-speed machining enhances both the quality and precision of parts, making multi-axis solutions ideal for intricate projects. Vietnamese shops have honed these skills, offering unmatched precision in their machining capabilities.

Custom Parts and Prototype Development

Custom machining services in Vietnam cater to specific industry needs, offering rapid prototyping that enables quick iterations and design improvements. Engineers work closely with clients to achieve desired outcomes, ensuring that prototypes are delivered with precision and speed.

Vietnamese machine shops excel in prototype development, leveraging their expertise to craft quality parts that meet exact specifications. Whether you’re looking for a one-off custom piece or an entirely new design, their services are tailored to deliver exceptional results.

Advanced Equipment and Technologies Used in Vietnamese Machining

Vietnamese machining shops are at the cutting edge of technology, investing in state-of-the-art equipment and tools that enhance their precision and capabilities.

State-of-the-Art CNC Machines and Tools

Vietnamese shops are committed to using the latest CNC machines to achieve superior performance. These advanced tools not only enhance precision but also boost the efficiency of manufacturing processes, ensuring that every product meets the highest standards.

Regular upgrades and maintenance ensure that the equipment remains at the forefront of global standards. CNC technology allows for complex and precise machining operations, making Vietnamese shops a reliable choice for your precision needs.

Automation and Robotics in Precision Machining

Automation is revolutionizing the precision machining industry in Vietnam. By increasing efficiency and reducing production time, automation allows shops to stay competitive in the global market. Robotics plays a crucial role, enhancing precision, especially in repetitive tasks that demand consistency.

Smart systems optimize workflow, improving overall productivity and ensuring that projects are completed on time. Vietnamese shops are leveraging these technologies to provide high-quality machining services that meet the demands of modern industries.

Innovative Technologies in Machining Services

Innovation is at the heart of Vietnamese machining services. From integrating 3D printing with traditional machining to utilizing IoT devices for real-time monitoring, Vietnamese shops are at the forefront of technological advancements. Laser machining offers precision for delicate and intricate parts, adding to the array of capabilities available.

Continuous R&D efforts are driving the adoption of new technologies, ensuring that Vietnamese machining services remain cutting-edge. This commitment to innovation means you can rely on these shops for the latest and greatest in precision machining.

Customer Reviews: What Clients Say About Vietnamese Machine Shops

Customer feedback is a testament to the quality and reliability of Vietnamese machine shops. Here’s what clients have to say about their experiences.

Testimonials from International Clients

International clients consistently praise the commitment to quality and precision demonstrated by Vietnamese shops. Positive feedback highlights the cost-effectiveness of services, with many clients appreciating the balance of quality and price.

Timely delivery of projects is another aspect that garners acclaim, with many clients acknowledging the reliability of Vietnamese shops in meeting deadlines. Strong customer relationships are a hallmark of these businesses, ensuring that clients feel valued and supported throughout their projects.

Quality and Precision: Client Satisfaction

Consistent quality has built trust with global partners, making Vietnamese precision machining services a preferred choice for many. Clients value the attention to detail and craftsmanship that goes into each project, with the results often exceeding expectations.

Long-term partnerships reflect the satisfaction and reliability that clients experience, with many returning for future projects. This ongoing collaboration underscores the effectiveness and quality of Vietnamese machining services.

Case Studies of Successful Projects

Successful projects are a testament to the capabilities of Vietnamese shops. Case studies highlight innovation in solving complex machining challenges, showcasing the versatility of Vietnamese services in handling diverse requirements.

Documented successes underscore the strategic advantages of choosing Vietnam for your machining needs. Whether it’s intricate aerospace components or durable industrial parts, Vietnamese shops consistently deliver exceptional results.

Success Stories: Notable Projects and Custom Parts Crafted in Vietnam

Vietnamese machine shops have a rich history of success stories that highlight their expertise and capabilities across various industries.

Aerospace Industry Projects

Vietnamese shops have delivered critical components for aerospace applications, ensuring that parts meet strict standards. Collaborative projects with global aerospace leaders have enhanced expertise, allowing Vietnamese shops to tackle complex challenges with confidence.

Advanced materials are often used to craft lightweight and durable parts, making Vietnamese shops a reliable partner for the aerospace industry. These projects demonstrate the precision and quality that define Vietnamese machining capabilities.

Medical Industry Innovations

In the medical field, precision machining supports the production of devices and equipment that meet stringent health standards. Innovative techniques are employed to address unique challenges, ensuring that medical products are both reliable and safe.

Vietnamese shops excel in delivering custom solutions, with a focus on high-quality production. This commitment to excellence makes them a trusted partner for medical innovations.

Automotive and Industrial Parts Successes

The automotive industry benefits from high-precision machining techniques that produce components with unmatched accuracy. Industrial parts are crafted with durability in mind, ensuring they withstand tough conditions.

Successful collaborations with automotive giants highlight the capabilities of Vietnamese shops, while the industrial sector benefits from versatile machining solutions. These successes showcase the breadth and depth of Vietnamese machining expertise.

Industries Served by Vietnamese Precision Machining Services

Vietnamese precision machining services cater to a wide array of industries, each benefiting from the quality and precision that define these services.

Aerospace and Defense

Aerospace companies rely on Vietnam for precision parts and components that meet the highest standards. Defense contracts further highlight the reliability and quality of services offered, with advanced machining supporting the development of cutting-edge technologies.

Strong quality control ensures compliance with international standards, making Vietnamese shops a trusted choice in the aerospace and defense sectors.

Medical Devices and Equipment

Manufacturers of medical devices depend on precision machining for complex parts that require meticulous attention to detail. Vietnamese shops deliver high-quality components, ensuring that health regulations are met throughout the production process.

With expertise in machining delicate materials, these shops offer key advantages that set them apart in the medical field.

Automotive and Heavy Industries

The automotive industry benefits from cost-effective precision machining solutions, while heavy industries require durable and precise parts for their equipment. Vietnamese shops offer solutions for both mass production and custom needs, collaborating with international companies to strengthen industry ties.

These collaborations enhance the capabilities of Vietnamese shops, making them a go-to choice for a wide range of industrial applications.

How to Select the Right Vietnamese Machine Shop for Your Needs

Choosing the right Vietnamese machine shop can make all the difference in your project’s success. Here’s how to evaluate your options effectively.

Evaluating Precision Machining Service Providers

When evaluating potential providers, consider their experience and expertise in your specific industry. Assess the range of services they offer, ensuring they align with your project needs. Technological capabilities and equipment used are also critical factors to consider.

Client feedback and past project successes provide valuable insights into a provider’s reliability and quality. A thorough evaluation ensures you choose a partner that matches your expectations.

Questions to Ask Potential Machine Shops

Before committing to a machine shop, ask about their experience with similar projects to yours. Inquire about their quality control processes and certifications, ensuring they meet industry standards.

Discuss turnaround times and delivery schedules, as these can impact your project’s timeline. Clarify cost structures and payment terms to avoid any surprises down the line. These questions help you make an informed decision.

Factors to Consider: Quality, Cost, and Turnaround Time

Balancing quality with cost is essential to achieving value for your investment. Consider the importance of quick turnaround for your project needs, as delays can be costly.

Evaluate the long-term benefits of choosing the right partner, including the potential for a lasting business relationship. These factors help you make a choice that supports your goals and ensures project success.

Understanding the Cost and Value of Precision Machining in Vietnam

Understanding the cost and value of precision machining in Vietnam can help you make informed decisions for your projects.

Breakdown of Machining Costs

In Vietnam, labor, materials, and overhead contribute to the overall cost of machining services. Advanced equipment and technology influence pricing structures, with efficient processes helping to keep costs competitive.

Transparency in pricing builds trust with clients, ensuring you know exactly what you’re paying for. This understanding of costs is crucial for budgeting and planning.

Balancing Cost with Quality and Precision

Cost-effective solutions in Vietnam do not compromise on quality or precision. Long-term savings result from investing in reliable machining services, ensuring consistent product standards.

Quality assurance processes are in place to guarantee that each part meets the highest standards. Strategic investments in technology enhance value for clients, making Vietnamese services a smart choice.

Long-term Value of Choosing Vietnamese Machining Services

Vietnamese shops offer a balance of quality, cost, and innovation that provides long-term value for clients. Partnerships provide stability and reliability, while continuous improvement efforts ensure future-ready solutions.

Choosing Vietnam for your machining services supports sustainable growth, offering a reliable partner for your projects.

Get in Touch: How to Contact Leading Precision Machine Shops in Vietnam

Reaching out to the right machine shop is the first step towards achieving your project goals. Here’s how to find and contact the best providers.

Finding the Best Machine Shop for Your Project

Research potential shops based on your specific project needs. Utilize industry directories and networks to identify top providers, considering both local and international recommendations for reliable options.

Evaluate their online presence and client testimonials for insights into their capabilities and reliability. This research ensures you choose a partner that aligns with your objectives.

Tips for Reaching Out and Building Relationships

When initiating contact, provide clear project details and expectations. Build rapport through regular communication and updates, establishing trust by being transparent and responsive to inquiries.

Fostering long-term relationships through collaboration and mutual goals ensures a successful partnership. These tips help you build strong connections with potential machining partners.

Resources for Further Contact and Information

Industry associations provide valuable directories and contact information, while trade shows and exhibitions offer networking opportunities. Online platforms connect you with potential machining partners, and reaching out to existing clients for referrals and recommendations can provide additional insights.

These resources help you find and connect with the best machine shops for your needs, ensuring a successful collaboration.

—

In summary, Vietnam’s precision CNC machining industry offers a wealth of opportunities for engineers, manufacturers, and anyone seeking high-quality, cost-effective machining solutions. With a focus on quality, innovation, and customer satisfaction, Vietnamese shops are well-equipped to meet the diverse needs of global clients. Could partnering with a Vietnamese machine shop be the game-changer your project needs?

Frequently Asked Questions

What is precision CNC machining?

Precision CNC machining involves using computer-controlled machines to create high-accuracy parts and components from various materials. The process is precise and efficient, making it ideal for industries like aerospace, automotive, and electronics. In Vietnam, this technology is gaining popularity due to its ability to produce complex designs with minimal waste and high repeatability.

Why is Vietnam becoming a hub for precision CNC machining?

Vietnam is emerging as a hub for precision CNC machining due to its skilled workforce, competitive labor costs, and growing investment in technology. Companies in Vietnam offer high-quality services at lower prices compared to Western countries, attracting international clients looking for cost-effective manufacturing solutions.

What materials can be used in TDB On Facebook?

In Vietnam, CNC machining can handle a variety of materials, including metals like aluminum, steel, and titanium, as well as plastics and composites. The choice of material depends on the specific requirements of the project, such as durability, weight, and cost, allowing for versatile applications across different industries.

How do I choose the right CNC machining service provider in Vietnam?

To choose the right CNC machining service provider in Vietnam, consider factors like the company’s experience, technology, and quality control processes. Look for providers with positive client testimonials, certifications, and the ability to handle your specific project requirements. Communicating clearly with potential providers will ensure that your expectations are met.

What are the benefits of outsourcing CNC machining to Vietnam?

Outsourcing CNC machining to Vietnam offers several benefits, including cost savings, access to skilled labor, and high-quality production. Vietnam’s strategic location in Asia also facilitates efficient shipping and logistics, making it an attractive option for companies looking to optimize their supply chains while maintaining high-quality standards.