Contract Manufacturer Leading Turnkey CNC Manufacturing Partner in Vietnam

Prototype, pilot, mass produce and ship ready-to-sell products with end-to-end manufacturing solutions, direct from our factories in Vietnam.

- Turnkey Manufacturing Support

- Engineering, Project Management & Design Support

- In-House Machined Parts & Assembly Services

How We Support Our Customers

TDB is your partner for high-mix, medium-to-high volume manufacturing. With robust engineering and purchasing support, deep application and process knowledge, and vertically integrated manufacturing facilities in Vietnam, we help customers develop, manufacture and ship custom products around the world in fields from agriculture to IOT.

Custom product manufacturing and in-house mechanical and electronic assembly, with quality ensured from prototype to production.

Turnkey mechanical, machining and aluminum housing build assembly, with qualily inspection to ensure your product are market-ready.

Flexible batch sizes, comprehensive quality control and quick turnaround.

Who We Do It For

Supporting Businesses from Prototyping to Mass Production

Industries & Businesses We Serve

TDB partners with companies at every stage of growth, providing scalable manufacturing and assembly solutions tailored to your needs.

- Startups & Innovators – Accelerate product development with rapid prototyping, DFM (Design for Manufacturability) support, and small-batch production—ideal for validating new concepts and preparing for launch.

- Growing Businesses & SMEs – Scale up confidently with flexible MOQs, cost-effective manufacturing, and robust quality assurance as your business expands and enters new markets.

- Enterprises & OEMs – Rely on TDB for large-scale production, turnkey assembly, integrated supply chain solutions, and global logistics to meet demanding timelines and volume requirements.

About TDB TECH

Your Partner in Precision Manufacturing

Founded in 2015 by a Vietnamese engineer based in Vietnam, TDB has grown from a five-person startup to a team of over 25 dedicated professionals, supported by robust engineering, quality, and operations teams. Our three state-of-the-art manufacturing facilities in Vietnam span 2,000 sq. m., strategically located in major industrial clusters, including northeast Vietnam.

- Startups & Innovators – Accelerate product development with rapid prototyping, DFM (Design for Manufacturability) support, and small-batch production—ideal for validating new concepts and preparing for launch.

- Fast & Scalable Production – Flexible manufacturing adapts to demand with high efficiency, producing over 6 million finished products annually.

- Global Options –Manufacturing operations in three countries provides our customers with flexibility in meeting their needs.

- Uncompromising Quality Control – A rigorous inspection process ensures reliability and consistency for customers in industries such as automotive, agriculture, mining, and consumer goods.

Manufacturing Processes

Vertically Integrated Solutions

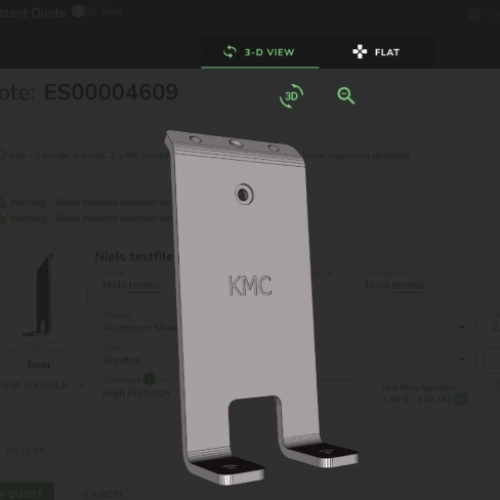

Turnkey production, testing and packaging of mechanical and electromechanical assemblies and sub-assemblies.

We specialize in transforming your ideas into reality with absolute precision. Whether you need high-volume production components.

We offer over 30 production grade materials, and take great care to ensure the right material is used for every CNC machined part.

From aerospace and robotics products to medical and automotive parts, we’re proud to create beautifully CNC machined parts for any and every industry.

We offer high-quality finishing processes for most CNC machined parts; including anodising, polishing and plating, heat treatment, powder coating and more.

Whether you’re after a one-off prototype or 100,000 units at the most competitive price, CNC machining is a go-to manufacturing method for rapid scalability.

We are dedicated to reducing friction at every process, ensuring you receive quickly. To be as delighted with the speed of delivery as their exceptional quality.

Our goal is to deliver products that are ready for your inventory and immediate sale, eliminating the need for further processing on your end.

Featured Products

A selection of custom-engineered mechanical and electro-mechanical products designed and manufactured by TDB Hanoi.

From Design to Delivery

A Streamlined, Step-by-Step Production Journey

Testimonials

What Our Clients Say

FAQS

Answers to common questions about our turnkey contract manufacturing services

1. How do you ensure quality control in your manufacturing facilities?

We maintain unified quality standards across our facilities in Vietnam. Our vertically integrated operations give us full control over each step of the manufacturing process—from fabrication to assembly—reducing quality risks that come from managing multiple vendors.

Clients benefit from real-time visibility into production status, inspections, and milestones through our digital quality system, ensuring consistency and transparency at every stage.

2. How do you ensure quality control in your manufacturing facilities?

We maintain unified quality standards across our facilities in Vietnam. Our vertically integrated operations give us full control over each step of the manufacturing process—from fabrication to assembly—reducing quality risks that come from managing multiple vendors.

Clients benefit from real-time visibility into production status, inspections, and milestones through our digital quality system, ensuring consistency and transparency at every stage.